881 E 57th Ave, Denver, CO 80216 | Monday-Friday 7am-4:30pm | (303) 872-5981

Industrial Motors & Machining Blog

by Industrial Motors & Machining Inc.

•

18 Apr, 2024

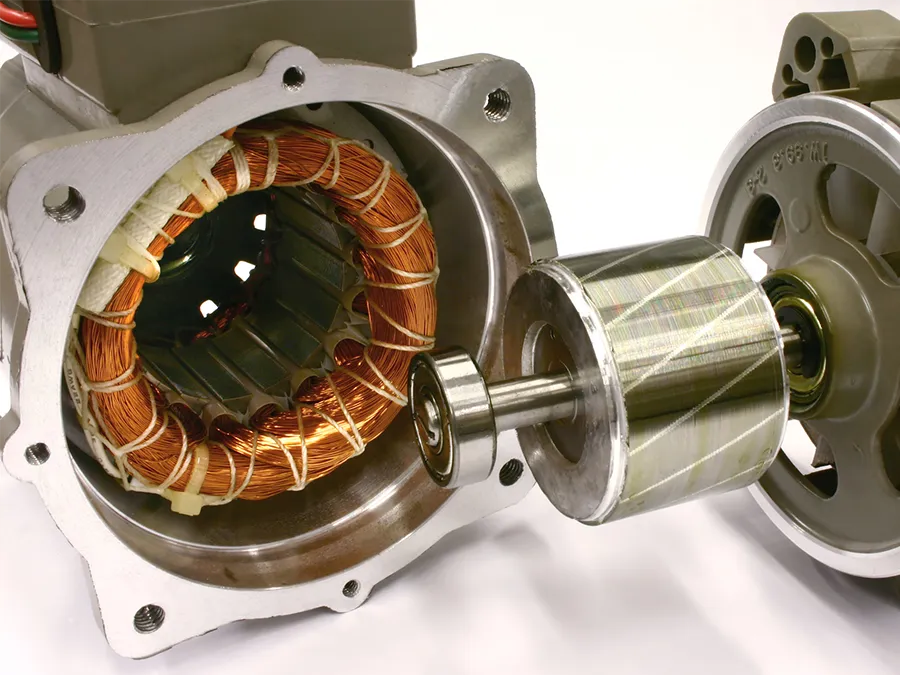

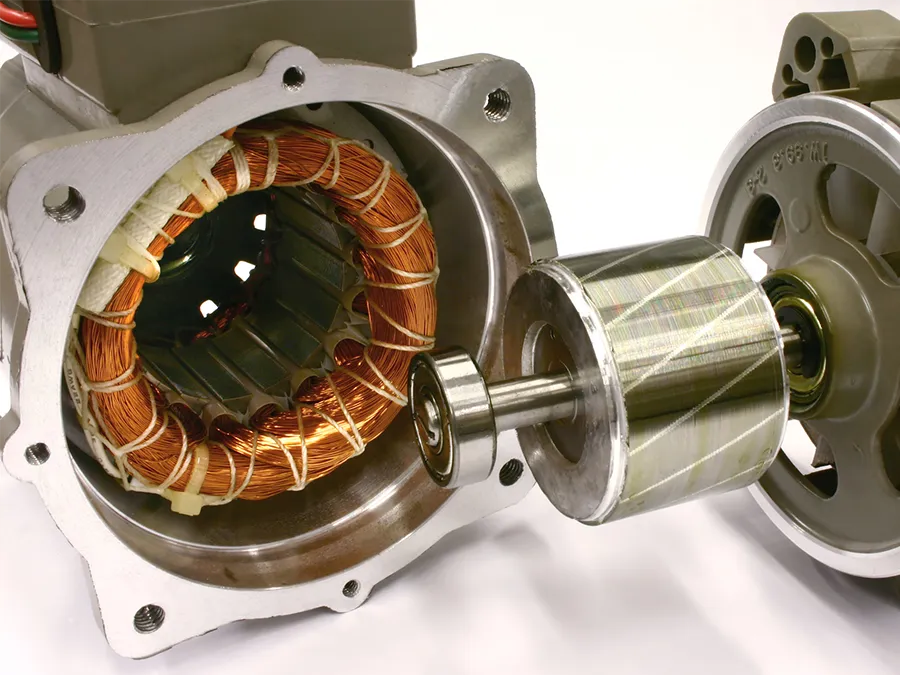

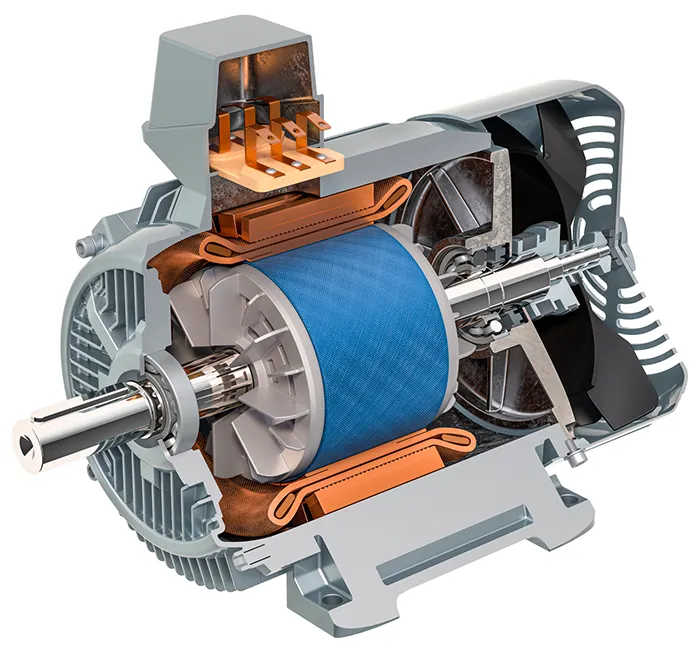

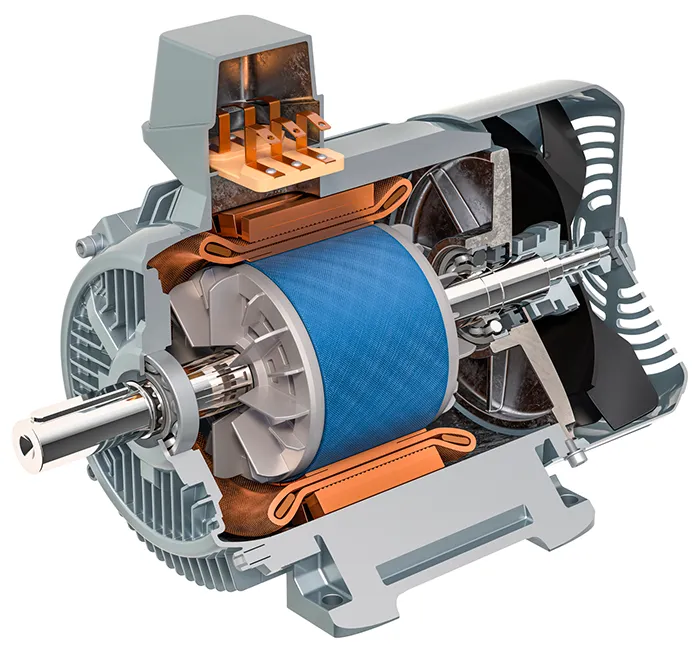

In our modern world, electric motors power everything from household appliances to industrial machinery. At Industrial Motors & Machining, we provide expert electric motor repair in Denver, and our team loves to share our knowledge of the industry. Here’s a look at four fascinating facts about electric motors. The First Electric Motor The first practical electric motor was invented by British scientist Michael Faraday in 1821. Faraday's simple apparatus consisted of a magnet immersed in a mercury bath, which demonstrated the conversion of electrical energy into mechanical motion. This breakthrough laid the foundation for the development of electric motors that would later power countless applications. Electric Motors Are Highly Efficient One of the remarkable qualities of electric motors is their efficiency. Unlike internal combustion engines, which waste a significant amount of energy as heat, electric motors can convert the vast majority of electrical energy into mechanical work. Modern electric motors typically operate at efficiencies exceeding 90%, making them an environmentally-friendly choice for propulsion and power generation. Electric Motors Are Everywhere If you just look around, you'll likely spot multiple electric motors in your vicinity. From the fan in your laptop to the compressor in your refrigerator, electric motors power countless devices in our daily lives. They are also prevalent in industrial settings, driving conveyor belts, pumps, and manufacturing equipment. Electric Motors Come in Various Types and Sizes Electric motors are not one-size-fits-all. Rather, they come in a wide range of types and sizes tailored to specific applications. The most common types include AC (alternating current) motors and DC (direct current) motors, each with its own advantages and limitations. Within these categories, there are further subdivisions such as induction motors, synchronous motors, brushed DC motors, and brushless DC motors. Also, electric motors vary in size from tiny micro motors used in consumer electronics to big industrial motors capable of generating thousands of horsepower. Electric Motor Sales & Repair in Denver, CO When you need electric motor sales and service in Denver and the surrounding area, contact Industrial Motors & Machining Inc. at 303-872-5981 . Feel free to give us a call today to ask us about our electric motor inventory and repair services!

by Industrial Motors & Machining Inc.

•

22 Mar, 2024

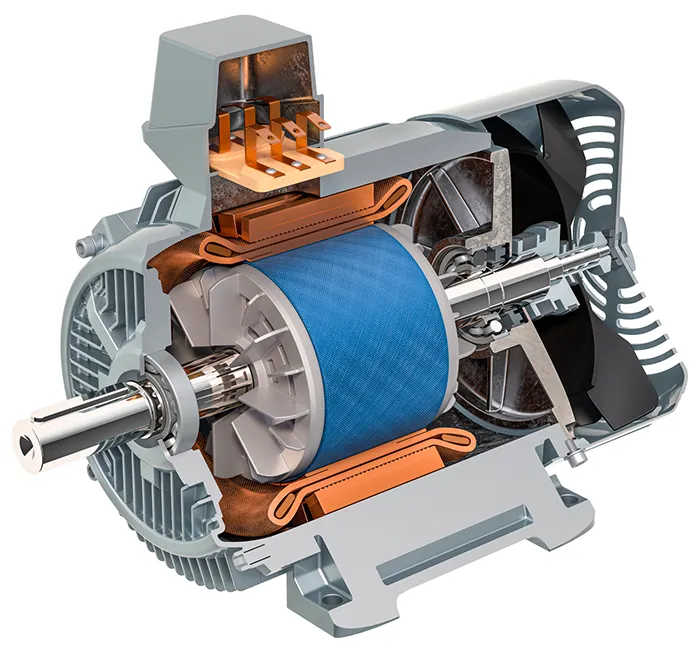

Electric motors are the workhorses behind numerous industrial, commercial, and residential applications. From powering machinery in factories to driving fans and pumps in HVAC systems, they play a crucial role in modern life. However, electric motors are prone to overheating, which can lead to breakdowns and even safety hazards. At Industrial Motors & Machining, we provide expert electric motor repair in Denver, including addressing issues with overheating. Here’s a look at four common reasons why electric motors overheat. Excessive Load Electric motors are designed to operate within specific load limits. When subjected to loads beyond their capacity, they work harder, generating more heat. Continuous operation under such conditions can cause overheating. Factors contributing to excessive loads include overloading the motor with heavy loads, running it at high speeds for prolonged periods, or using it in applications for which it's not intended. Poor Ventilation Adequate ventilation is essential for dissipating the heat generated during motor operation. If the motor's ventilation system is inadequate or blocked, heat buildup becomes inevitable. Common culprits include dust, dirt, debris, or improper installation that obstructs airflow around the motor. Also, operating motors in confined spaces with insufficient ventilation exacerbates the problem. Insufficient Cooling Cooling mechanisms such as fans or cooling fins are integral parts of electric motors, assisting in heat dissipation. When these cooling components malfunction, the motor's temperature can quickly rise. Issues with cooling mechanisms should be addressed as soon as possible. Inadequate Lubrication Proper lubrication is crucial for reducing friction and heat generation within electric motors. Insufficient or improper lubrication of bearings and moving parts can result in increased friction, leading to overheating. Factors contributing to inadequate lubrication include using the wrong type of lubricant, lubricant contamination, or failing to keep up with lubrication maintenance schedules. Electric Motor Repair in Denver, CO When you need electric motor repair in Denver and the surrounding area, contact Industrial Motors & Machining Inc. at (303) 872-5981 . At our nearby machine shop, we can expertly address your electric motor needs. Feel free to give us a call today to ask us about our electric motor repair services!

by Industrial Motors & Machining Inc.

•

22 Feb, 2024

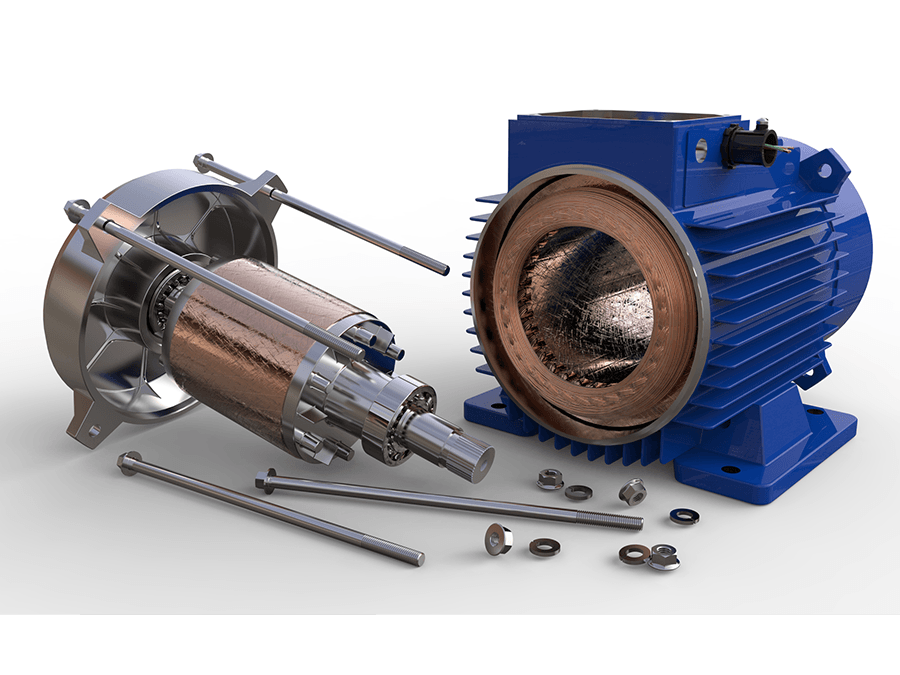

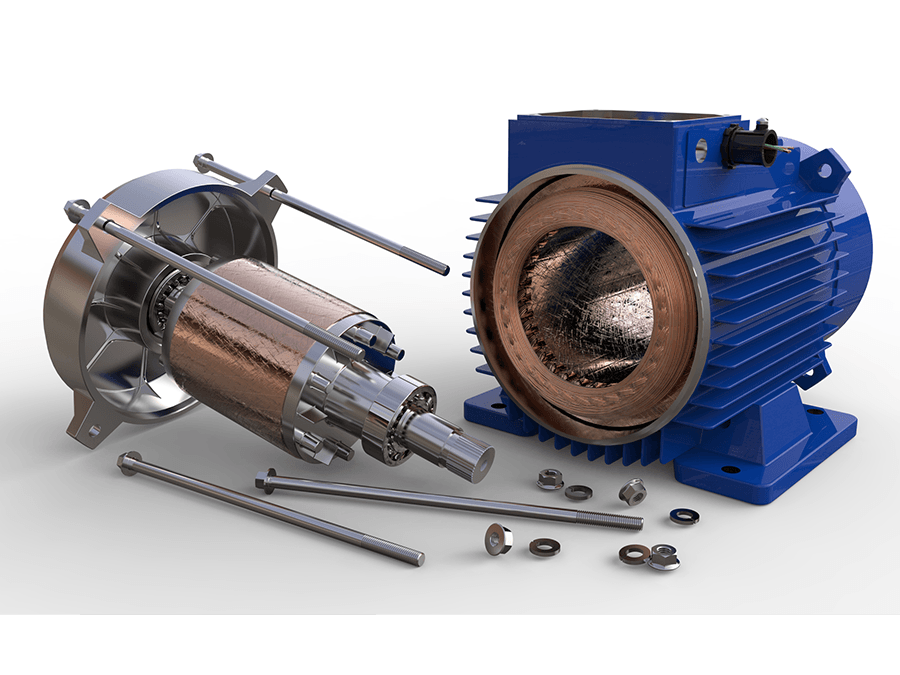

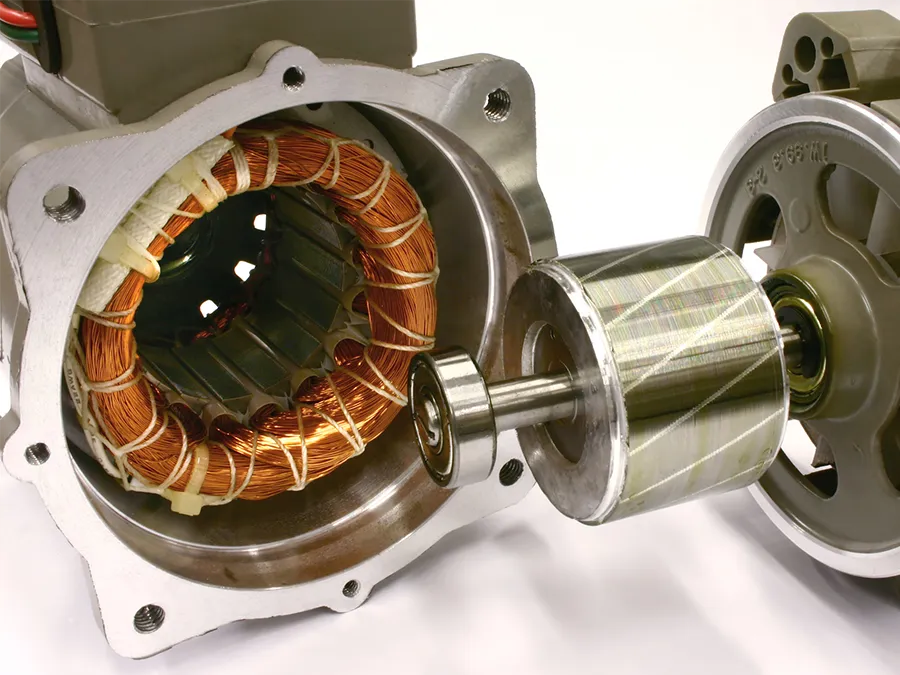

Electric motors power everything from household appliances to industrial machinery. However, despite their usefulness, certain issues can cause electric motors to fail. If you suspect that there’s a problem developing with your electric motor, it’s best to bring it to a professional before it worsens. At Industrial Motors & Machining, we provide expert electric motor service in the greater Denver area. Here are five common causes of electric motor failure. Overheating One of the primary culprits behind electric motor failures is overheating. Motors generate heat during operation, and excessive temperatures can lead to insulation breakdown, bearing damage, and overall degradation of internal components. Overheating may result from prolonged operation beyond the motor's rated capacity, inadequate cooling, or a malfunctioning cooling system. Electrical Imbalances Electrical imbalances within the motor system can contribute to premature failure. Issues such as voltage imbalances, phase unbalance, or improper connections can lead to uneven loading of motor windings, causing increased heat and stress on certain components. Contamination and Moisture Electric motors, especially those in industrial settings, are vulnerable to contaminants and moisture. Dust, dirt, and other particulates can infiltrate the motor housing, leading to increased friction, wear, and potential insulation breakdown. Moisture can corrode internal components and compromise the motor's performance. Implementing proper sealing and maintaining a controlled environment can help to protect electric motors from contamination and moisture. Mechanical Wear and Tear Regular use can result in mechanical wear and tear, affecting various motor components such as bearings, brushes, and gears. Through frequent operation, these components may deteriorate, leading to increased friction, vibration, and potential failure. Regular inspections, lubrication, and timely replacement of worn-out parts are important preventive measures to extend the lifespan of electric motors. Inadequate Maintenance One of the most avoidable causes of electric motor failure is inadequate maintenance. Neglecting routine inspections, lubrication, and necessary repairs can allow minor issues to escalate into major problems. Electric Motor Sales & Repair in Denver, CO When you need electric motor sales and service in Denver and the surrounding area, contact Industrial Motors & Machining Inc. at 303-872-5981 . Feel free to give us a call today to ask us about our electric motor inventory and repair services!

by Industrial Motors & Machining Inc.

•

18 Apr, 2024

In our modern world, electric motors power everything from household appliances to industrial machinery. At Industrial Motors & Machining, we provide expert electric motor repair in Denver, and our team loves to share our knowledge of the industry. Here’s a look at four fascinating facts about electric motors. The First Electric Motor The first practical electric motor was invented by British scientist Michael Faraday in 1821. Faraday's simple apparatus consisted of a magnet immersed in a mercury bath, which demonstrated the conversion of electrical energy into mechanical motion. This breakthrough laid the foundation for the development of electric motors that would later power countless applications. Electric Motors Are Highly Efficient One of the remarkable qualities of electric motors is their efficiency. Unlike internal combustion engines, which waste a significant amount of energy as heat, electric motors can convert the vast majority of electrical energy into mechanical work. Modern electric motors typically operate at efficiencies exceeding 90%, making them an environmentally-friendly choice for propulsion and power generation. Electric Motors Are Everywhere If you just look around, you'll likely spot multiple electric motors in your vicinity. From the fan in your laptop to the compressor in your refrigerator, electric motors power countless devices in our daily lives. They are also prevalent in industrial settings, driving conveyor belts, pumps, and manufacturing equipment. Electric Motors Come in Various Types and Sizes Electric motors are not one-size-fits-all. Rather, they come in a wide range of types and sizes tailored to specific applications. The most common types include AC (alternating current) motors and DC (direct current) motors, each with its own advantages and limitations. Within these categories, there are further subdivisions such as induction motors, synchronous motors, brushed DC motors, and brushless DC motors. Also, electric motors vary in size from tiny micro motors used in consumer electronics to big industrial motors capable of generating thousands of horsepower. Electric Motor Sales & Repair in Denver, CO When you need electric motor sales and service in Denver and the surrounding area, contact Industrial Motors & Machining Inc. at 303-872-5981 . Feel free to give us a call today to ask us about our electric motor inventory and repair services!

by Industrial Motors & Machining Inc.

•

22 Mar, 2024

Electric motors are the workhorses behind numerous industrial, commercial, and residential applications. From powering machinery in factories to driving fans and pumps in HVAC systems, they play a crucial role in modern life. However, electric motors are prone to overheating, which can lead to breakdowns and even safety hazards. At Industrial Motors & Machining, we provide expert electric motor repair in Denver, including addressing issues with overheating. Here’s a look at four common reasons why electric motors overheat. Excessive Load Electric motors are designed to operate within specific load limits. When subjected to loads beyond their capacity, they work harder, generating more heat. Continuous operation under such conditions can cause overheating. Factors contributing to excessive loads include overloading the motor with heavy loads, running it at high speeds for prolonged periods, or using it in applications for which it's not intended. Poor Ventilation Adequate ventilation is essential for dissipating the heat generated during motor operation. If the motor's ventilation system is inadequate or blocked, heat buildup becomes inevitable. Common culprits include dust, dirt, debris, or improper installation that obstructs airflow around the motor. Also, operating motors in confined spaces with insufficient ventilation exacerbates the problem. Insufficient Cooling Cooling mechanisms such as fans or cooling fins are integral parts of electric motors, assisting in heat dissipation. When these cooling components malfunction, the motor's temperature can quickly rise. Issues with cooling mechanisms should be addressed as soon as possible. Inadequate Lubrication Proper lubrication is crucial for reducing friction and heat generation within electric motors. Insufficient or improper lubrication of bearings and moving parts can result in increased friction, leading to overheating. Factors contributing to inadequate lubrication include using the wrong type of lubricant, lubricant contamination, or failing to keep up with lubrication maintenance schedules. Electric Motor Repair in Denver, CO When you need electric motor repair in Denver and the surrounding area, contact Industrial Motors & Machining Inc. at (303) 872-5981 . At our nearby machine shop, we can expertly address your electric motor needs. Feel free to give us a call today to ask us about our electric motor repair services!

by Industrial Motors & Machining Inc.

•

22 Feb, 2024

Electric motors power everything from household appliances to industrial machinery. However, despite their usefulness, certain issues can cause electric motors to fail. If you suspect that there’s a problem developing with your electric motor, it’s best to bring it to a professional before it worsens. At Industrial Motors & Machining, we provide expert electric motor service in the greater Denver area. Here are five common causes of electric motor failure. Overheating One of the primary culprits behind electric motor failures is overheating. Motors generate heat during operation, and excessive temperatures can lead to insulation breakdown, bearing damage, and overall degradation of internal components. Overheating may result from prolonged operation beyond the motor's rated capacity, inadequate cooling, or a malfunctioning cooling system. Electrical Imbalances Electrical imbalances within the motor system can contribute to premature failure. Issues such as voltage imbalances, phase unbalance, or improper connections can lead to uneven loading of motor windings, causing increased heat and stress on certain components. Contamination and Moisture Electric motors, especially those in industrial settings, are vulnerable to contaminants and moisture. Dust, dirt, and other particulates can infiltrate the motor housing, leading to increased friction, wear, and potential insulation breakdown. Moisture can corrode internal components and compromise the motor's performance. Implementing proper sealing and maintaining a controlled environment can help to protect electric motors from contamination and moisture. Mechanical Wear and Tear Regular use can result in mechanical wear and tear, affecting various motor components such as bearings, brushes, and gears. Through frequent operation, these components may deteriorate, leading to increased friction, vibration, and potential failure. Regular inspections, lubrication, and timely replacement of worn-out parts are important preventive measures to extend the lifespan of electric motors. Inadequate Maintenance One of the most avoidable causes of electric motor failure is inadequate maintenance. Neglecting routine inspections, lubrication, and necessary repairs can allow minor issues to escalate into major problems. Electric Motor Sales & Repair in Denver, CO When you need electric motor sales and service in Denver and the surrounding area, contact Industrial Motors & Machining Inc. at 303-872-5981 . Feel free to give us a call today to ask us about our electric motor inventory and repair services!

by Industrial Motors & Machining Inc.

•

22 Jan, 2024

Electric motors power countless machines and devices in our daily lives. From industrial machinery to household appliances, electric motors play a crucial role in making our world run smoothly. However, like any other mechanical system, they require maintenance to attain optimal performance and lifespan. At Industrial Motors & Machining, we provide top-quality electric motor service in the greater Denver area. We can expertly address your electric motor needs. Here’s a look at four electric motor maintenance tips. Keep it Clean One of the simplest yet most effective ways to maintain electric motors is to keep them clean. Dust, dirt, and debris can accumulate on the motor's surface and inside its components, leading to increased friction and heat. Regularly clean the motor's exterior using a soft brush or compressed air to remove any contaminants. Additionally, consider implementing a routine inspection schedule to ensure that the internal components remain free from debris. Monitor Temperature Overheating is a common cause of electric motor failure. Monitoring the motor's temperature is crucial to prevent damage. Ensure that the motor operates within its specified temperature range. If the motor feels excessively hot to the touch, it may be a sign of a problem. Inspect and clean cooling mechanisms, such as fans and vents, to promote efficient heat dissipation. Proper Lubrication Proper lubrication is fundamental to reducing friction and wear in electric motors. Regularly inspect and replace lubricants according to the manufacturer's guidelines. Ensure that the lubrication points are adequately greased, taking care not to over-lubricate, as this can also lead to issues. Electrical Connections and Inspections Faulty electrical connections can lead to a range of issues, including motor failure and safety hazards. It’s wise to regularly inspect and tighten electrical connections to prevent issues with terminals. Electrical testing, including voltage and current measurements, can help identify potential issues with the motor's electrical system. Electric Motor Sales & Service in Denver, CO When you need electric motor sales and service in Denver and the surrounding area, contact Industrial Motors & Machining Inc. at 303-872-5981 . Feel free to give us a call today to ask us about our electric motor inventory and repair services!

by Industrial Motors & Machining Inc.

•

19 Dec, 2023

Electric motors play a crucial role in powering a wide array of machines, contributing to our daily lives in ways we often don’t even realize. From kitchen blenders to electric vehicles, modern electric motors are the driving force behind numerous products that improve our day-to-day lives. At Industrial Motors & Machining Inc., we provide top-quality electric motor sales and service in the greater Denver area. Here are five common electric motor applications. Home Appliances Electric motors power an assortment of home appliances. Refrigerators, washing machines, vacuum cleaners, and electric fans all utilize electric motors to perform their functions efficiently. These motors are designed for reliability, providing the necessary power to keep our homes running smoothly. HVAC Systems Heating, ventilation, and air conditioning (HVAC) systems are essential for maintaining a comfortable indoor environment. Electric motors power the fans that circulate air throughout buildings, ensuring a consistent and controlled climate. These motors contribute to energy efficiency by allowing precise control over the airflow and temperature. Industrial Machinery In the industrial sector, electric motors are the workhorses behind a variety of machines. Conveyor belts, pumps, compressors, and manufacturing equipment all rely on electric motors to power their operations. The versatility of electric motors makes them indispensable in optimizing production processes and enhancing overall efficiency. Power Tools From cordless drills to electric saws, power tools have become an integral part of construction, woodworking, and DIY projects. Electric motors in power tools deliver the necessary torque and speed to perform various tasks. The compact and lightweight design of these motors contributes to the portability and convenience of power tools. Aerospace Applications Electric motors are making their mark in the aerospace industry, particularly in aircraft systems. Electric propulsion systems are becoming more prevalent, providing efficient and environmentally friendly alternatives to traditional aviation technologies. Also, electric motors power components such as landing gear systems and fuel pumps. Electric Motor Sales & Service in Denver, CO When you need electric motor sales and service in Denver and the surrounding area, contact Industrial Motors & Machining Inc. at 303-872-5981 . Feel free to give us a call today to ask us about our electric motor inventory and repair services!

Request a Free Estimate

Fill in the form below and we'll have a representative contact you!

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.