5 Issues that Cause Electric Motor Failure

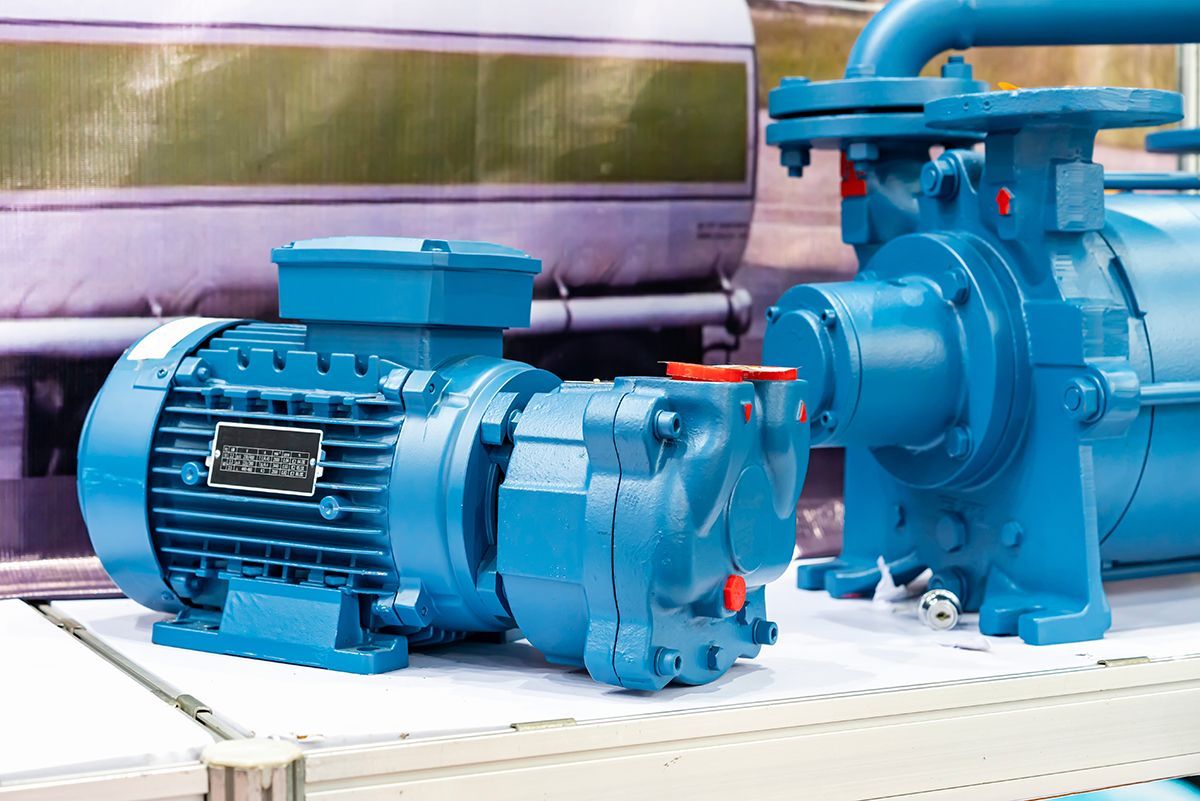

Electric motors power everything from household appliances to industrial machinery. However, despite their usefulness, certain issues can cause electric motors to fail. If you suspect that there’s a problem developing with your electric motor, it’s best to bring it to a professional before it worsens. At Industrial Motors & Machining, we provide expert electric motor service in the greater Denver area. Here are five common causes of electric motor failure.

Overheating

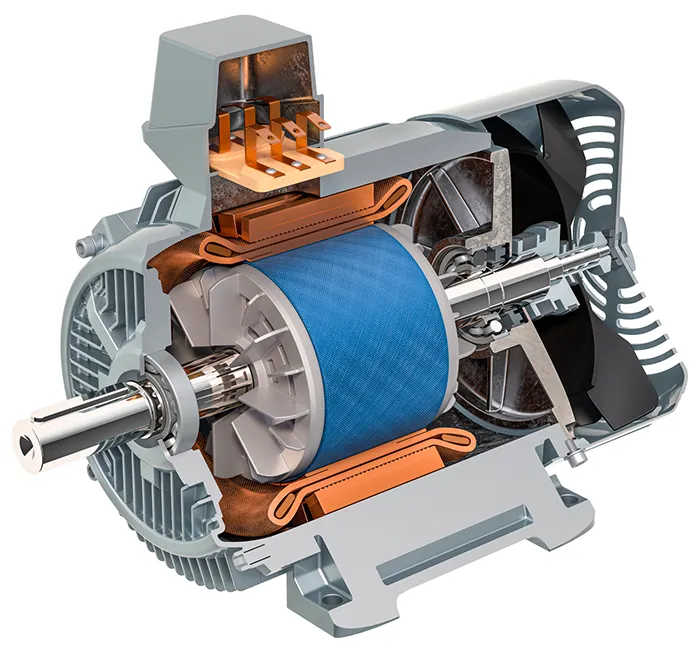

One of the primary culprits behind electric motor failures is overheating. Motors generate heat during operation, and excessive temperatures can lead to insulation breakdown, bearing damage, and overall degradation of internal components. Overheating may result from prolonged operation beyond the motor's rated capacity, inadequate cooling, or a malfunctioning cooling system.

Electrical Imbalances

Electrical imbalances within the motor system can contribute to premature failure. Issues such as voltage imbalances, phase unbalance, or improper connections can lead to uneven loading of motor windings, causing increased heat and stress on certain components.

Contamination and Moisture

Electric motors, especially those in industrial settings, are vulnerable to contaminants and moisture. Dust, dirt, and other particulates can infiltrate the motor housing, leading to increased friction, wear, and potential insulation breakdown. Moisture can corrode internal components and compromise the motor's performance. Implementing proper sealing and maintaining a controlled environment can help to protect electric motors from contamination and moisture.

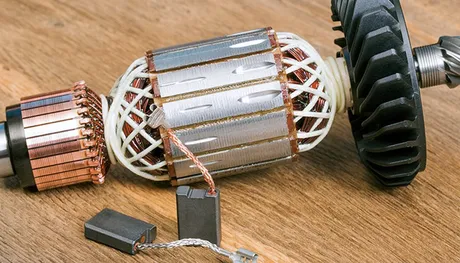

Mechanical Wear and Tear

Regular use can result in mechanical wear and tear, affecting various motor components such as bearings, brushes, and gears. Through frequent operation, these components may deteriorate, leading to increased friction, vibration, and potential failure. Regular inspections, lubrication, and timely replacement of worn-out parts are important preventive measures to extend the lifespan of electric motors.

Inadequate Maintenance

One of the most avoidable causes of electric motor failure is inadequate maintenance. Neglecting routine inspections, lubrication, and necessary repairs can allow minor issues to escalate into major problems.

Electric Motor Sales & Repair in Denver, CO

When you need

electric motor sales and service in Denver

and the surrounding area, contact Industrial Motors & Machining Inc. at

303-872-5981. Feel free to give us a call today to ask us about our electric motor inventory and repair services!