4 Maintenance Tips for Keeping Electric Motors Healthy

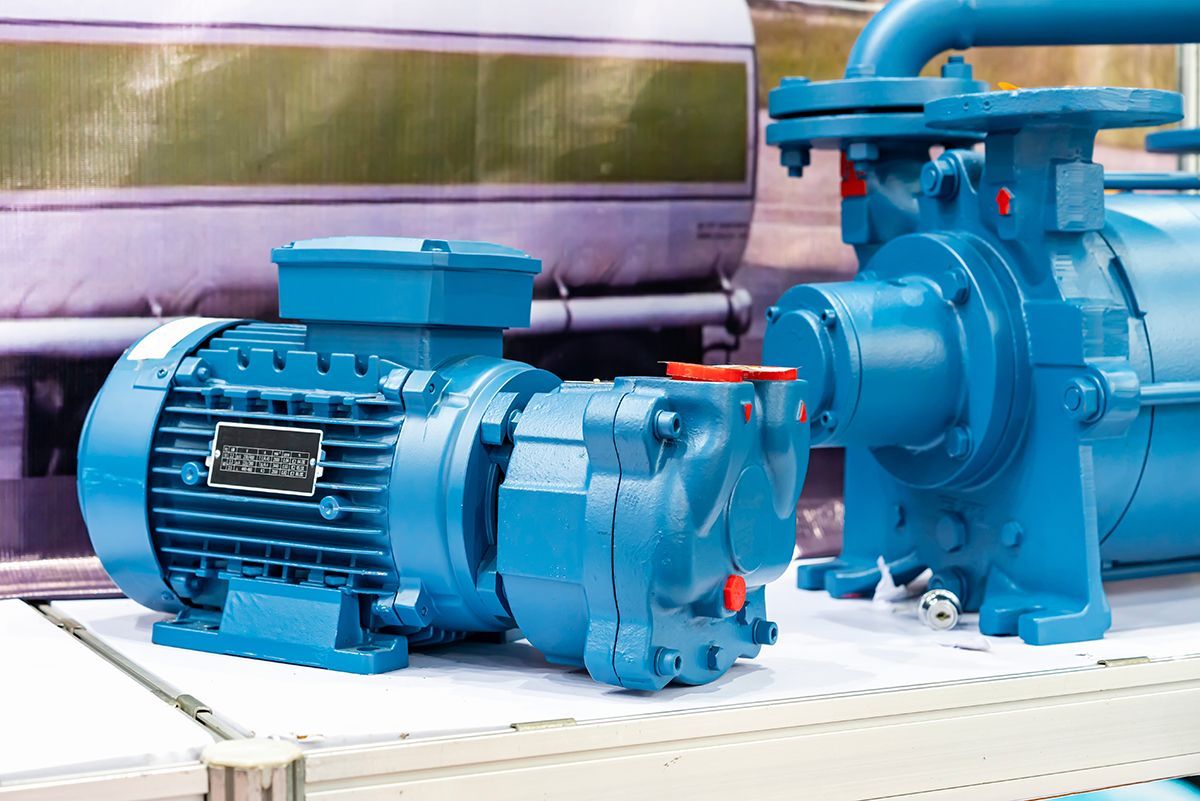

Electric motors are essential components in a wide range of industries, from manufacturing to HVAC systems. Keeping them in peak condition helps ensure efficiency, longevity, and safety. Without proper maintenance, electric motors can suffer from overheating, mechanical wear, and electrical failures. By following these maintenance tips, you can help keep your electric motors running smoothly.

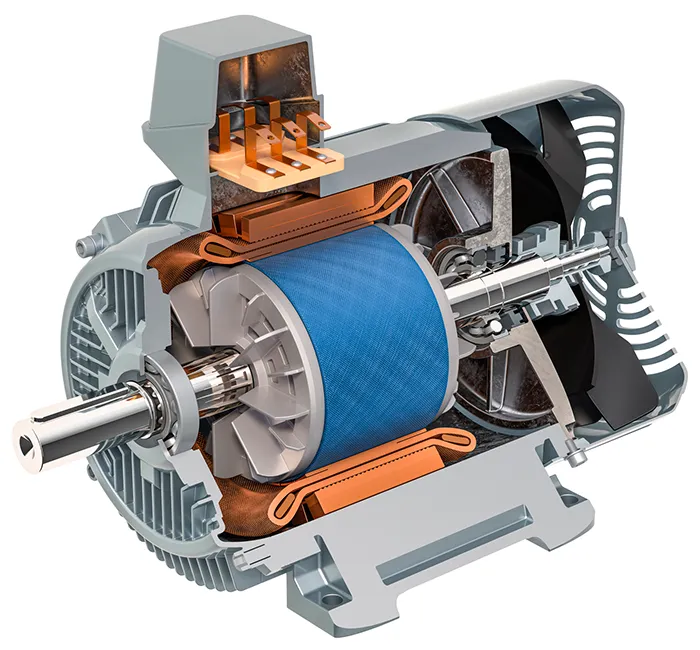

Keep Motors Clean and Free of Debris

Dirt, dust, and debris can accumulate in and around an electric motor, causing overheating and reducing efficiency. Excess buildup can obstruct ventilation, leading to higher operating temperatures and increased wear on internal components. Regularly cleaning the motor, including cooling fans and vents, helps ensure proper airflow and prevents overheating. Using compressed air or vacuuming around motor components can remove unwanted particles and keep the motor running more efficiently.

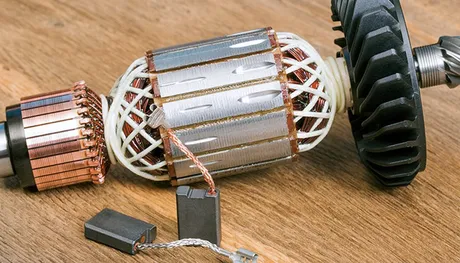

Lubricate Bearings and Moving Parts

Proper lubrication is critical for reducing friction and preventing wear on bearings and other moving parts. Over time, insufficient lubrication can lead to overheating, increased resistance, and premature failure. However, over-lubrication can also be harmful, leading to grease buildup and potential contamination. Following the manufacturer’s lubrication schedule and using the recommended type of lubricant helps ensure optimal performance and longevity.

Monitor Temperature and Ventilation

Excessive heat is one of the most common causes of electric motor failure. Motors should operate within their recommended temperature range, as overheating can damage insulation and reduce efficiency. Ensuring proper ventilation and airflow around the motor prevents excessive heat buildup. Regularly checking temperature readings and addressing any abnormal increases can help prevent damage before it becomes a serious issue.

Inspect Electrical Connections and Wiring

Loose or damaged electrical connections can lead to power fluctuations, voltage drops, and motor inefficiencies. Over time, vibrations and operational stresses can cause connections to loosen or deteriorate. Routine inspections of wiring, terminals, and connections help prevent electrical failures. Tightening loose connections and replacing worn-out wiring enhances motor reliability.

Electric Motor Sales & Service in Denver, CO

When you need

electric motor sales and service in Denver, CO

and the surrounding area, contact Industrial Motors & Machining Inc. at

303-872-5981.

We can expertly address your electric motor repair and maintenance needs.

Feel free to give us a call to ask us about our electric motor inventory and repair services!